introduction of jaw crusher

Jaw Crusher SpringerLink

2023.6.21 Jaw crusher is crushing equipment that works with two jaw plates, one fixed and the other movable. The movable jaw plate approaches the fixed jaw plate

Read More

Jaw Crusher Explained - saVRee

Article Introduction to Crushing Comminution is the process by which mined ore is reduced in size to make for easier processing. The strict definition is ‘the action of taking a material, specifically mineral ore, and reducing it to

Read More

Jaw Crusher - ScienceDirect

2016.1.1 This mathematical concept of jaw crusher operation has been developed for modelling and subsequent throughput prediction from jaw crushers (see Chapter 10). 4.4

Read More

(PDF) DESIGN AND OPERATIONS CHALLENGES OF

2017.6.30 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that...

Read More

A fundamental model of an industrial-scale jaw crusher

2017.5.1 In a jaw crusher, the material is crushed between two plates: a static plate and a moving plate. Compression is applied by the moving plate, and the material

Read More

Retsch : 产品 : 粉碎设备 : 颚式粉碎仪

A jaw crusher is always at the very front of the sample preparation chain, precrushing all hard and brittle materials. The RETSCH jaw crusher range is primarily used in

Read More

Optimisation of the swinging jaw design for a single toggle jaw crusher ...

2022.9.20 Abstract. This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for

Read More

Crusher - an overview ScienceDirect Topics

Mechanical Crushing and Grinding. Oleg D. Neikov, in Handbook of Non-Ferrous Metal Powders, 2009 Crushers. Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size. They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer

Read More

How it Works: Crushers, Grinding Mills and

2017.6.2 Crusher buckets are excavator attachments that contain two jaws, one fixed and one that moves back and forth, much like a jaw crusher. Grinding Mills and Pulverizers. Grinding mills and pulverizers are the

Read More

Jaw crusher-CSDN博客

2013.11.29 Introduction of Jaw Crusher:Jaw Crusher series are based on years’ experience and technology development. The co..._jaw和chin Jaw crusher 最新推荐文章于 2024-01-15 19:33:42 发布 cuiy0060 最新推荐文章于 2024-01-15 19:33:42 发布 阅读量336 收藏 点赞数 ...

Read More

Jaw Crusher--Henan Zhongke Engineering Technology

Generally, jaw crusher can be used for both primary and secondary crushing. It can be used to crush the hardest rock and the materials with particle size around 125~1020mm and compressive strength less than 320MPa. 2) Working principle of jaw crusher machine. Motor drives belt and belt pulley, makes moving jaw up and down through eccentric shaft.

Read More

Stone Crushers: A Technical Review on Significant Part of

2022.5.13 The cone crusher performance is analyzed by using bonded particle method to study rock breakage mechanics. DEMisusedasatool for the analysis 2012 Quist [20] Sweden 2 Primary crusher Jaw crusher Expt. + Nume FEM analysis can be used as a powerful tool for analyzing the failure of the component in jaw crusher 2013 Rusi´ nski et

Read More

RIVLQJOH WRJJOHMDZ FUXVKHU

2. Factors affecting jaw crusher capacity The mathematical model of the working process of the crusher should take into account many factors. Operating experience and investigations have shown that the performance of jaw crushers significantly depends on their design and the motion law of its function element – the moving jaw [5], [6].

Read More

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017.3.4 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the ...

Read More

6 Granite Crushers for Efficient Granite Rock Crushing

2023.5.12 The large jaw crusher can crush 1,000 tons of granite stones per hour. Due to its simple structure and small size, the price of jaw crusher is much cheaper than other rock crushing machine. The granularity of granite products can be adjusted to meet the different production needs of users. Stable operation and low failure rate reduce ...

Read More

Improvement of Jaw Crusher Design by DEM FEA

2022.1.30 Fig.3 shows the configuration of the jaw crusher and geometrical and operation parameters are given in Table 1. Jaw crusher mainly, consist of moving jaw, eccentric shaft, flywheel and toggle plate. The jaw has specific motion to break feed material by the means of eccentric shaft. while jaw width is 1100 mm, gaps from upper side is 650

Read More

Crushers: Breaking Down the History of these Machines

2016.6.10 Blake’s crusher was announced in 1857 and patented in 1858. Perhaps surprisingly, the same basic design is still in use today for rock crushers. In the years following the design of the Blake Jaw Crusher, another type of crusher was designed. A gyratory crusher was patented by Philetus W. Gates in 1881.

Read More

Retsch : 产品 : 粉碎设备 : 颚式粉碎仪

颚式研磨仪应用领域. A jaw crusher is always at the very front of the sample preparation chain, precrushing all hard and brittle materials. The RETSCH jaw crusher range is primarily used in laboratories and pilot plants under rough conditions but are also suitable for on-line quality control of raw materials. The main fields of ...

Read More

Introduction to Jaw Crushers: Understanding the Basics

2023.12.30 The foundation of a jaw crusher is the frame, which provides structural support and houses the eccentric shaft, which is a critical component for generating crushing motion. Connected to the frame ...

Read More

Jaw crusher PPT - SlideShare

2014.12.9 18. • Single Toggle Jaw Crusher • In the single toggle jaw crushers, the swing jaw is suspended on the eccentric shaft which leads to a much more compact design than that of the double toggle jaw crusher. •

Read More

Design and Construction of Rock Crushing Machine from

2019.8.24 Introduction Crushing is one of the preliminary stages in mineral processing from the ore. The process is required to reduce rocks and lumps to smaller pieces. Rollers or jaw crushers are employed in this situation. The jaw crusher is a rocks or lumps reduction machine that employs two hardened manganese steel jaws, with one in

Read More

A fundamental model of an industrial-scale jaw crusher

2017.5.1 To achieve a model using physical modelling techniques, the machine of interest, a jaw crusher in this case, has to be broken down into smaller subsystems and modelled separately, for example, breakage, dynamics or pressure, as seen in Fig. 1.For this research, the modelling approach is similar to the approach used by Evertsson

Read More

Types of Crushers: What You Need to Know - Machinery

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing. The three main stages of crushing are primary, secondary, and tertiary - all of which have their own unique benefits.

Read More

Jaw Crusher: Range, Working Principle, Application - DSMAC

2022.2.22 DSMAC Jaw Crusher Introduction. DSMAC Jaw Crushers are configured for primary crushing of even hardest rock. Our Jaw Crushers are crushing without rubbing Minimum dust Oil lubrication, devise having Oil/Grease lubrication system. The company crushers are designed for long life service with minimum maintenance for hard, tough,

Read More

Crusher Wear Parts: What They Are and Why They Matter

2023.2.18 Jaw crusher wear parts include jaw plates, cheek plates, wedges, and toggle plates. Jaw plates are the most critical component and come in different profiles to suit different types of crushing applications. Cheek plates protect the sides of the crusher frame and reduce wear on the jaw dies. Wedges are used to adjust the gap between the

Read More

Crushing 101 – Different types of crushers for distinctive needs

2020.12.17 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

Read More

Introduction to Jaw Crushers: Understanding the Basics

2023.12.30 The foundation of a jaw crusher is the frame, which provides structural support and houses the eccentric shaft, which is a critical component for generating crushing motion. Eccentric Shaft ...

Read More

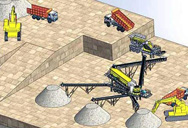

Aggregate Crushers - High-efficiency And Eco

The above is a brief introduction to the types of aggregate crushing equipment. You can choose suitable aggregate equipment according to your own needs and parameters. ... One mobile crusher equips with an APG

Read More

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER

A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine the time and energy required to crush the material. Economy of the crushing process is partly dependent on the angle of nip. Productivity of the crusher can

Read More

Assessing the energy efficiency of a jaw crusher - ScienceDirect

2014.9.1 The main reason for this inefficiency is in the random distribution of forces on the particles inside the crusher. With certain simplifications, the theoretical energy efficiency of comminution can be estimated to fall between 5 and 10 % (Legendre Zevenhoven, 2014) while the measured energy efficiency in actual comminution testing

Read More

The Importance of Jaw Crusher Design Features in Crushing

2023.2.28 The design of a jaw crusher plays a crucial role in its operation and efficiency, and this article will explore some of the key features and benefits of jaw crusher design. Jaw Crusher Design: Introduction. The primary function of a jaw crusher is to reduce large rocks into smaller sizes for use in construction, mining, and other industries.

Read More

CRUSHING PowerPoint Presentation, free download

2014.8.2 CRUSHING . Exp # 1: Machine Study of Laboratory jaw Crusher and to perform a crushing test on the given sample. CONTENTS. Introduction to Crushing Introduction to Jaw Crusher Types of Jaw Crusher Construction of Jaw crusher Free Crushing Choked Crushing Slideshow 2808776 by dimaia.

Read More

“Computer Aided Design of Jaw crusher” - 911 Metallurgist

2016.12.19 Basics of Jaw Crusher 1.1 Introduction Crushing is the process of reducing the size of solid particles into definite smaller sizes. Jaw crushers are major size reduction machines used in mechanical, metallurgical and allied industries. The crusher crushes the feed by some moving units against a stationary unit or against

Read More

Dynamics Analysis and Chaos Identification of Compound Pendulum Jaw ...

2022.11.24 A dynamic model of the working mechanism of a compound pendulum jaw crusher with clearance is established by the Lagrange multiplier method (LMD) based on the L-N contact force model and modified Coulomb friction force model. The correctness of the dynamic model is verified by MATLAB and Adams comparison simulation, and the

Read More

“Computer Aided Design of Jaw crusher” - National

2010.5.14 Jaw crusher movement is guided by pivoting one end of the swinging jaw. and an eccentric motion located at the opposite end. [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws .For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46"

Read More

JCE系列欧版颚式破碎机 JCE Series Jaw Crusher SKJ ...

2013.5.20 JCE欧版鄂式破碎机主要由机架,偏心轴,破碎腔,保险装置,排料口调整装置等部分组成。. JCE series Jaw Crusher are mainly divided into five parts: frame, eccentric shaft, crushing cavity, safety device and discharge opening adjusting device. 1、机架部分:由侧板、前箱组件、后箱焊件等组成。. Frame ...

Read More

Stone Crusher Machine Manufacturer Jaw Crusher

china stone crusher manufacturer. BANGDE stone crusher machine manufacturer is specialized in researching and manufacturing mining crusher equipments and their spare parts. We mainly specializes in producing crushing, feeding and screening equipment, including jaw crusher, cone crusher, sand making machine, etc.

Read More

- آلات مناولة المواد

- jual mata pisau سنگ شکن

- محجر الجرانيت في كودلو بارابانا بنغالور

- دستگاه های سنگ شکن فروش کلاسه بندی شده

- عمودی شرکت تولید سیمان آسیاب غلتکی

- قطعات یدکی قطعات از تولید کننده های سنگ شکن

- الكاولين تجهيز المصنع بأحدث التقنيات

- ویژگی های اصل عامل فک سنگ شکن

- sel سنگ شکن آسیاب

- موج شکن آرژانتین کارخانه

- موردي قطع معدات التعدين

- كسارة الصخور تعمل بالطاقة الغاز كين

- تورسا محطم مجموعة الحجر المحرز في الهند

- سنگ شکن قابل حمل سنگ شکن در آفریقای جنوبی

- معادن و سنگ شکن ها در العین