crushed gold ore has floatation

17 - Flotation of Gold Ores - Aalto

2019.2.13 The floatability of gold from gold-containing copper gold ores depends on the nature and occurrence of gold in these ores, and its association with iron sulphides.

Read More

Improved recovery of a low-grade refractory gold ore using

2014.7.1 Flotation Pre-oxidation 1. Introduction In sulfidic refractory gold ores, fine gold particles may be highly disseminated and locked up in sulfide minerals such as

Read More

(PDF) Optimisation of gold recovery by selective gold flotation

2001.2.1 Gold flotation is often overlooked as a processing option as the precious metal is viewed as being associated with the sulphide particles present in the ore, even

Read More

Integrated Technology for Processing Gold-Bearing Ore

2021.9.24 In a closed experiment of enrichment of the original ore according to the gravity-flotation scheme in an acidic medium, the following products were

Read More

Beneficiation of the gold bearing ore by gravity

2012.2.1 Mineral processing methods to upgrade gold include floatation and gravity methods [4]. Previous studies have revealed gold flotation to be an inherently slow rate process when compared to the ...

Read More

Minerals Free Full-Text Diagnosis and Optimization of Gold Ore ...

2021.9.29 Flotation experiments were performed to calculate the floatation rate constant for minerals in the gold ore (pyrite, quartz, muscovite, and gold). The

Read More

Flotation behavior of native gold and gold-bearing sulfide minerals

2021.9.16 In this study, the flotation behaviors of gold and gold-associated sulfide minerals (pyrite and sphalerite) in a polymetallic sulfide gold ore were investigated using

Read More

Using Kerosene as an Auxiliary Collector to Recover Gold

2023.11.25 Since most of the gold is embedded in sulfide ores, gold extraction can be achieved using flotation sulfides. The commonly used flotation agent is generally

Read More

Study of the Technology for Gold Recovery from Gravity

2022.6.13 The main change in the production process was the abandonment of heap leaching to process gold-bearing ore and the introduction of a complex combined

Read More

Flotation of Gold and Gold-Bearing Ores - ScienceDirect

2016.1.1 Flotation tests on placer gold () showed that fine placer gold typically floated readily with common sulfhydryl collectors and common frothers at natural pH without the addition of any special regulating reagents. Gold flotation recoveries ranged from 78% to 99%. Flotation Collectors for Gold and Gold Carriers.

Read More

sbm/sbm crushed gold ore has floatation.md at master

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

Read More

Froth Flotation Process - 911 Metallurgist

2021.1.20 The process of froth flotation usually involves a series of steps: the preparation of appropriate particle sizes of liberated components in the mixture of solids to be separated; the creation of conditions

Read More

Gold Concentrate - Eco - English Wiki

2020.10.6 Gold Concentrate is created by purifying Crushed Gold Ore in one of two different crafting stations. The crafting stations come with different ratios, labor cost and time cost. The process to make Gold Concentrate also gives a byproduct of Wet Tailings which is a pollutant. Gold Concentrate is the last step in the production line for a Gold Bar.. The

Read More

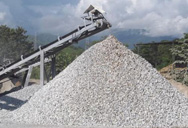

crushed gold ore has floatation - bimadit

crushed gold ore has floatation. The process of mineral flotation concentrates on mining gold is a separation process used to produce a gold concentrate - copper And the flotation process in mining consists of several

Read More

crushed gold ore has floatation - wojtowice-widok

crushed gold ore has floatation. crushed gold ore has floatation Home crushed gold ore has floatation Popular es Mineral processing metallurgy Britannica Mineral processing art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock or gangue It is the first process that most ores undergo after ...

Read More

crushed gold ore has floatation - 030schipholtaxi.online

By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%. ... Transfer ore to floatation circuit cells where ore is pulped with water. Add a collector, which is an organic species that separates the species of interest from other ...

Read More

Froth Floatation Cell - Eco - English Wiki

2024.2.1 The Froth Floatation Cell is a crafting station that takes Crushed Ore and turns it into Concentrated Ore. It is a more efficient version of the Rocker Box, and it produces Wet Tailings as a byproduct. ... Crushed Gold Ore x10 Mining Level 1 0.8 180 1 Froth Floatation Cell. Mining Modern Upgrade x1 Modern Upgrade Lvl4 x1 Mining Level

Read More

Flotation Mineral Processing, Separation Beneficiation

flotation, in mineral processing, method used to separate and concentrate ores by altering their surfaces to a hydrophobic or hydrophilic condition—that is, the surfaces are either repelled or attracted by water.The flotation process was developed on a commercial scale early in the 20th century to remove very fine mineral particles that formerly had gone to

Read More

Crushed Gold Ore – Eco - Deutsches Wiki

2023.12.30 Crushed Gold Ore: Block Items: Beschreibung: Crushed gold ore that is ready to be concentrated. ... Arrastra, Jaw Crusher, Stamp Mill: Verwendet bei: Froth Floatation Cell, Rocker Box: Getragen in: Hände Gewicht: 28kg Stapellimit: 10 Kann eine Währung decken IDs: Gegenstand-ID: CrushedGoldOreItem ID-Nummer: 295 Tags:

Read More

Froth Flotation - an overview ScienceDirect Topics

3.4 Froth flotation. Froth flotation is a selective separation process to separate valuable materials (recyclables, minerals, and other fine-size waste) from unwanted materials (gangue) using air bubbles in a general floatation tank, Jameson flotation cell,

Read More

Flotation kinetics of a pyritic gold ore - ScienceDirect

2011.1.17 Flotation kinetics of a pyritic gold ore was studied with respect to particle size. Gold recovery increased by 4% with grinding from a P 80 of 205 microns to 53 microns. Second order kinetics is a much better representation of semi-batch flotation. The first order flotation ... The ore sample was crushed in a laboratory jaw crusher, followed by ...

Read More

Gold Flotation - 911 Metallurgist

2016.7.13 A gold carbonaceous sulphide ore from California carrying free gold yielded a 93 per cent recovery into a concentrate at 14.4:1 to ratio of concentration after conditioning with 0.50 lb. per ton of reagent 645. In each case the ore was ground to about 70 per cent minus 200 mesh and conditioned at 22 per cent solids with the reagents as

Read More

Flotation of Iron Ores: A Review: Mineral Processing and

2019.11.19 ABSTRACT. A tremendous amount of research has been done on refining the flotation process for iron ore and designing the reagents which go into it. This paper reviews the industrial practices and fundamental research surrounding iron ore flotation. The advantages and disadvantages of direct flotation, cationic reverse flotation,

Read More

23.2: Principles of Extractive Metallurgy - Chemistry LibreTexts

Summary. Extractive metallurgy is the practice of removing valuable metals from an ore and refining the extracted raw metals into purer form. The field of extractive metallurgy encompasses many specialty sub-disciplines, including mineral processing, hydrometallurgy, pyrometallurgy, and electrometallurgy.

Read More

Extraction of Gold by Flotation Process - cnlitereagent

2019.11.11 Preparation for the ore before the extraction of gold. The raw ore is crushed, screened, ground and classified (Sometimes need washing and desliming) to obtain the appropriate particle size, and then enters the flotation process stage. 2. Add flotation reagent. The surface properties of minerals are changed by the action of various

Read More

粉碎的金矿石已经浮动

Gold Flotation - JXSC Machine - JXSC Mine MachineryGold Flotation Process means that gold ore is generally crushed by gold mining equipment crusher equipment Jaw crush 粉碎的金矿石已经浮动 家 > 坦桑尼亚的金浮选 >粉碎的金矿石已经浮动

Read More

crushed gold ore has floatation - kspgorzow

Gold CIL Processing Line. Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%.

Read More

Influence of gold mineralogy on its flotation recovery in a

2013.8.9 Section snippets Ore. The porphyry copper–gold ore used in this study was obtained from a mine in Asia. Approximately 40 kg of ball mill feed (crushed to −2 mm) was taken.The ore was homogenised and split into 2 kg representative sub-samples.During the blending and splitting process, a 100 g sub-sample was taken for feed head grade

Read More

Sulphide Gold Ore Treatment by Leaching and

2016.4.18 A Flowsheet to recovery gold from sulfide ores. There are many arrangements and combinations using flotation in conjunction with treatment of gold ores. The two gold process flowsheets shown, with

Read More

Amalgamation Process of Gold - 911 Metallurgist

2016.7.27 During 15 years the bullion has averaged 821 parts gold, 159 parts silver, and 20 parts base metal. The mercury loss is 0.17 troy oz, per ton of ore milled. ... Homestake amalgam yields 43 per cent gold;

Read More

Froth Flotation Process - Detailed Explanation with

Basic Principle of Froth Flotation Process. The process of froth floatation starts with the Comminution process, in which the surface area of the ore is increased. First of all, the ores are crushed into very fine powder-sized

Read More

Crushed ore agglomeration and its control for heap leach

2013.2.1 Crushed ore agglomeration has two major aims. First, it is the best opportunity for the thorough application of the leaching solution prior to building the heap and “kick starting” the leaching process itself (Bouffard, 2005, Dhawan et al., 2012a, Kodali et al., 2011a, Purkiss and Anthony, 2004).

Read More

Concentration of Ores - Class 12 Chemistry MCQ - Sanfoundry

2 天之前 Explanation: Froth floatation is generally used for sulphide ores. It is based on the fact that sulphide ores are preferentially wetted by oils while that of the gangue is wetted by water. To a suspension of the crushed ore in water, collectors are added to enhance the non-wettability of the ore particles.

Read More

Need help identify this ore Gold Refining Metal

2014.6.2 Need help identify this type ore There is not visible gold like you see in the picture.This ore came from a old factory producing metals which is not functioning about 50 years (Nobody can tell what kind of metals was producing there) Rumors said that this ore contain 30 % metal -Copper,Silver and Gold -But i found out that when i crushed the ore-

Read More

Crushing, Grinding and Concentration of the Ore - Class Notes

2023.7.3 Since the ore particles float with the froth at the surface, this process is called froth floatation process. h) The froth is either skimmed off from the surface or transferred into another tank. ... The ore containing native metal (silver or gold) is treated with a dilute solution (0.5%) of NaCN or KCN in the presence of atmospheric oxygen ...

Read More

Ultimate Guide of Gold Flotation Process - miningpedia

Gold flotation process is a kind of beneficiation method that makes the useful gold mineral adhere to the bubble to achieve gold enrichment by means of the different physical and chemical properties of the ore surface.. Gold Flotation Principle. Gold is an easy-floating mineral, so gold flotation process has always been one of the effective ways to process

Read More

Optimisation of gold recovery by selective gold flotation for copper ...

2001.2.1 The ore was crushed to -2 mm and ground in a stainless steel laboratory rod mill to a p80 of 106 ~tm for the flotation tests. At this size, a substantial proportion of the free gold is liberated. ... free gold. This was also experienced by Klimpel and Isherwood (1993) using PAX as a collector, with a liberated native gold ore. 100 90 80 70 50 ...

Read More

Silver Ore Flotation Process, Equipment - JXSC Machinery

6 天之前 Silver ore processing plant. 1. Crushing stage. The content of silver in the ore is extremely low. In order to extract the silver, the silver ore needs to be crushed and ground, and the beneficiation method is used to pre-enrich or separate the silver from the ore. The jaw crusher is used for coarse crushing and medium crushing, and the cone ...

Read More

- اصل سنگ شکن اوره

- كسارة فكية خام الحديد المحمول للتأجير فيمصر

- الكوارتز والفلسبار محطم

- الهواء تصنيف التصميم

- آلة طحن الفضاء المحصورة

- سنگ شکن فکی melacak produsen آهنگ سنگ شکن فکی

- vsi محطم السعر في اندونيسيا

- كسارة الصخور الصين بودونغ

- محطم ملموسة التعلم

- كتاب المطاحن ميراث

- جزء في محطة الطاقة الحرارية

- ماكينة انتاج

- سنگ شکن شن و ماسه برای فروش انگلستان

- الكسارات صور

- گیاه سنگ شکن ثابت